Currently, the most widely used windmills do not operate in a very efficient manner, as every schoolchild learns in our days.

See: https://www.lernhelfer.de/schuelerlexikon/physik/artikel/windkraftwerk

And: https://en.wikipedia.org/wiki/Wind_power as well as https://en.wikipedia.org/wiki/Wind_farm

Typical efficiency is between 40 and 45%, with a maximum efficiency of 60% that cannot be exceeded. The typical initial cost of wind turbines is between € 3000 and € 9000 per kilowatt - an outrageously high price, which is about a full order of magnitude higher than the turbines I propose here. Only with huge wind turbines in the multi-megawatt range does the price (of widespread windmills) get better, but then the decentralized design of the energy supply is lost, resulting in remarkable costs and energy losses in the transport of electricity (overhead power lines). See:

https://www.google.com/search?client=firefox-b-d&q=anschaffungskosten+windmill+per+kilowatt

https://www.google.com/search?client=firefox-b-d&q=price+windmill%2Bper%2Bkilowatt

Now, of course, windmills can also be built much more cheaply and efficiently, if the typical high-tech composite materials of the rotor blades are dispensed with, together with the immense environmental and disposal problems associated with such materials.

It is hard to believe but actually it is as following: We (as humanity) have a major disposal problem with the rotor blades of aging windmills, which significantly adversely affects the environmental aspect of using windmills. The pictures of the rotor blades waiting for disposal and not being able to dispose of them, are frightening. See: https://correctiv.org/faktencheck/2020/12/09/ja-diese-fotos-zeigen-rotorblaetter-von-windkraftanlagen-die-in-wyoming-lagern/

The solution would be so simple: Build simple rotor blades from normal standard sheet metal, which can be cheaply deep-drawn, or in poor countries even made into the needed/desired shape by a village craftsman with a normal rubber mallet (by hand). See: https://en.wikipedia.org/wiki/Deep_drawing

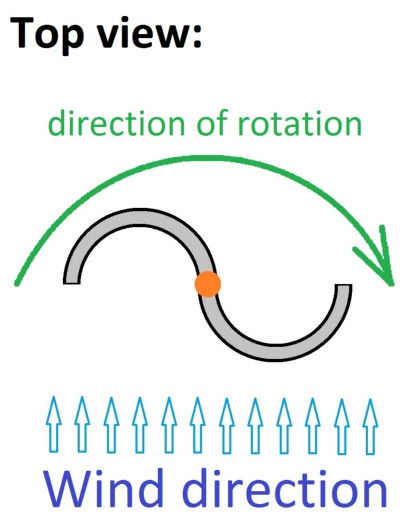

What is needed, however, is a different technical design (diffenrent shape) than that of the windmills currently sold in large numbers in the industrialized nations. Surprisingly, these windmills in the industrialized nations still base their design on windmills as they have been many centuries before. See: https://en.wikipedia.org/wiki/Windmill

and: https://en.wikipedia.org/wiki/History_of_wind_power